Upgrade of upper reservoir increases power production efficiency

The Background

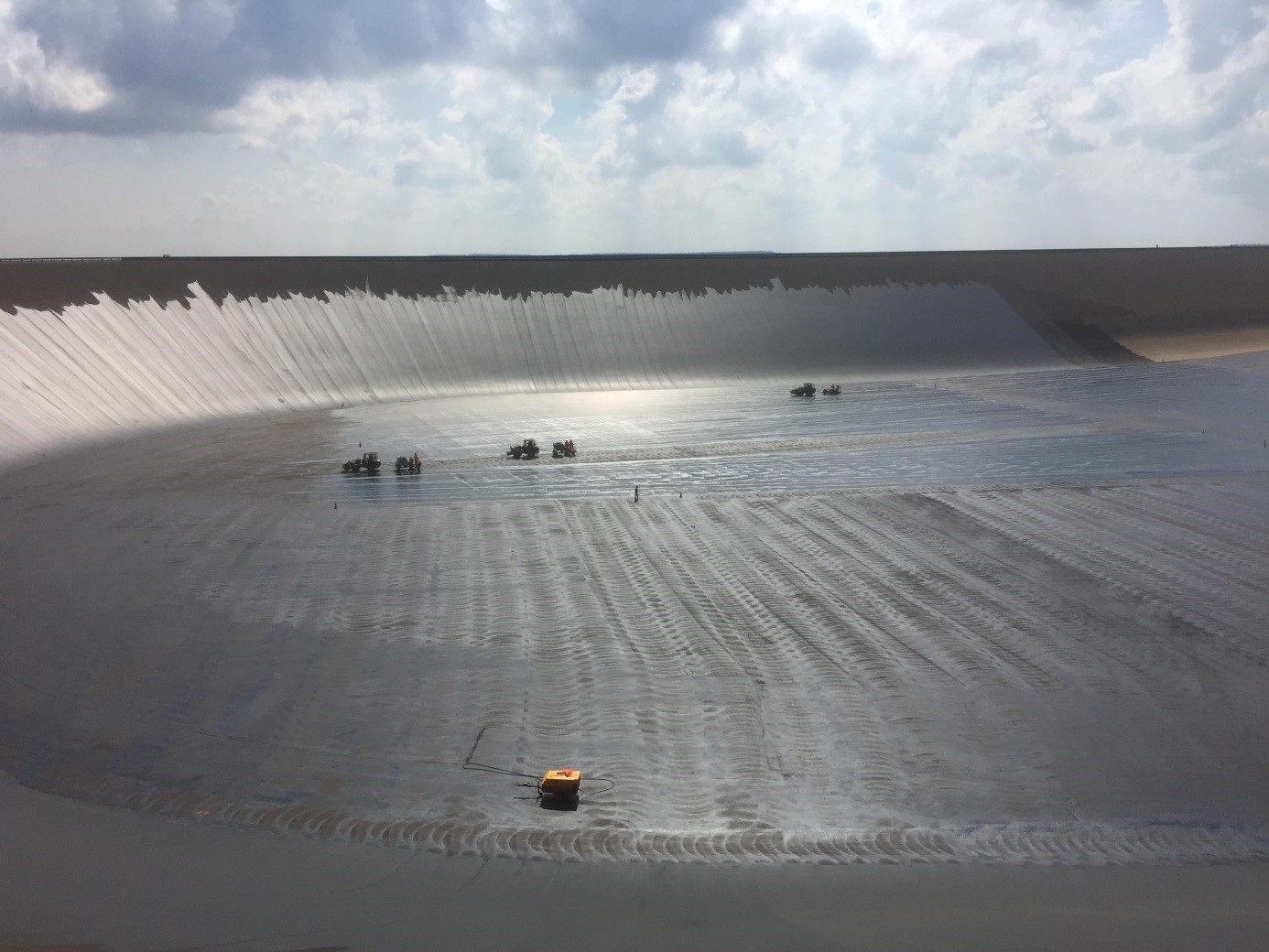

Goldisthal pump storage scheme is situated 50 km south of Erfurt in the Thuringian Mountains, Germany. The power station, operated by Vattenfall Hydropower Generation, has a power output of 1,060 MW and is the largest pump storage plant in Europe. The upper reservoir, which has a capacity of 12,000,000 m3 water, is lined with Dense Asphaltic Concrete (DAC) and it required a new mastic coating, covering a surface area of 330,000 m2. Mastic consists of bitumen, filler and sometimes sand and is spread onto the dense layer in a liquid form. It protects the DAC against UV radiation and creates an elastic film at the surface.

The accumulation of sediments in a reservoir, when at a certain thickness and composition can result in enormous shrinking forces while drying. A mastic coating can help to reduce sedimentation and so reduce these shrinking forces. The mastic seals the pores of the lining, which reduces vulnerability to attack by mechanical forces.

To complete the required works, WALO needed to clean the sediments from the lower part of the slope and a third of the base and then apply the new mastic coating. By having the lower part of the slope and the upper parts of the base sealed, Vattenfall can significantly increase the amount of usable water for power production.

The Challenge

The variable weather conditions in the Thuringian mountains and the need to keep the reservoir operational for as long as possible meant that there was considerable time pressure to complete the works in a limited time. WALO had four to five teams working alongside each other seven days a week to compensate for delays caused by bad weather. The reservoir was only empty for four weeks and all the works were completed in just six weeks.